Who we are

Founded in 1973, Formaplás started its activity in the injection of thermosets having, over time, expanded its work to the manufacture of injection molds for plastic and aluminum, cutting and stamping tools, injection of thermoplastics and thermosets, stamping and assembly. With a team of highly specialized employees, evolved production equipment, and an efficient organization system, Formaplás intends to be recognized by its partners as a reference in the plastics, stamping, and assembly sector.

Formaplás is focused on the future and on all solutions able to improve the quality of its products.

TARGET

MARKETS

MARKETS

With an activity that extends to different activity areas, FORMAPLÁS has focused on developing solutions for the following sectors:

AUTOMOTIVE INDUSTRY

Driving innovation in the Automotive Industry – where performance meets precision.

CONSUMING GOODS

Elevate your lifestyle with Consuming Goods – quality, style, and convenience in every choice.

ELETRICAL INDUSTRY

Powering progress in the Electrical Industry – where innovation sparks efficiency and connectivity.

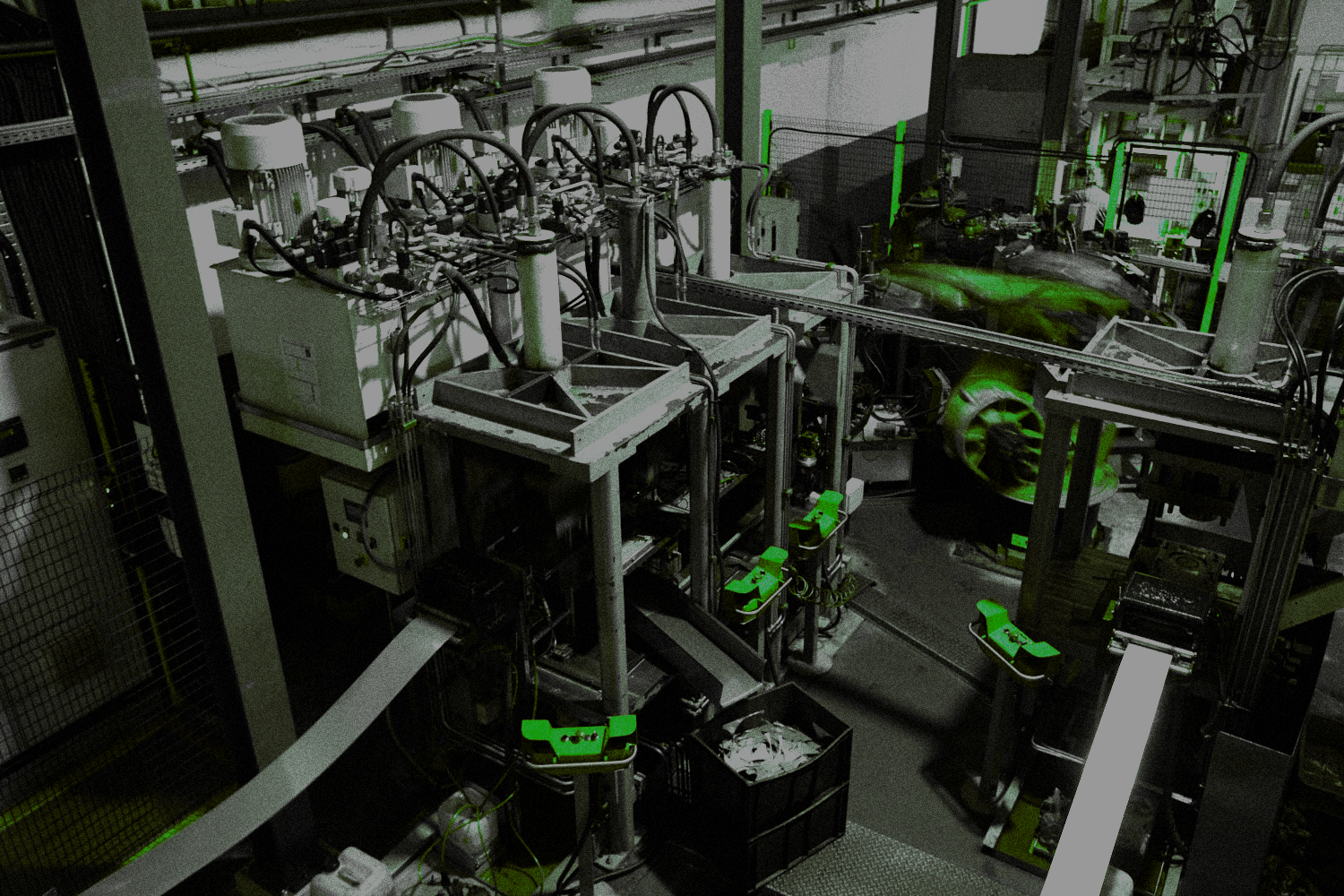

Injection Moulding Machines

Precision molding is our expertise with the 60-ton Battenfeld injection machine, an integral part of our cutting-edge facility, ensuring top-quality components for diverse industries.

Choose reliability and precision with the 150-ton Battenfeld injection machine, a key asset owned by our company. We specialize in delivering accurate and top-quality plastic injection parts for various applications.

Elevate your projects with the 180-ton Battenfeld injection machine, an exclusive asset owned by our company. We specialize in precision molding for various applications, delivering excellence.

Experience precision and efficiency with our 180-ton Engel injection machine. Owned by us, it plays a pivotal role in our commitment to delivering high-quality plastic injection parts for a range of industries.

Power your production with our 260-ton Engel injection machine, a cornerstone of our state-of-the-art facility. Exclusive to our operations, it ensures unmatched performance and versatility in plastic molding.

Our exclusively owned 270-ton Battenfeld injection machine is the epitome of efficiency. We leverage its capabilities to deliver optimal results in precision molding, meeting the unique demands of our clients.

Explore new possibilities with the 400-ton Engel injection machine, exclusively owned by our company. It is a powerhouse for large-scale production, combining precision and speed to meet the diverse needs of our clientele.

Toggle Machine

Type

Servo-hydraulic

Type of drive

< 4.200 kN

Clamping Force

Begining

1973

Formaplás Foundation

Formaplás Foundation was established by António Alves and Arnaldo Silva. During its early years, the company specialized in the production of thermosetting (bakelite) materials and molds. The founders' vision laid the groundwork for Formaplás journey in the industry.

1990

Beginning of its export process

During that period, FORMAPLÁS exclusively exported thermosetting products. This focused approach marked a significant phase in the company's history as it established a presence in the global market with its specialized offerings.

1995

Flama Group Integration

António Alves assumes full ownership of the company, integrating it into the FLAMA group. This strategic move further solidifies the company's position within the group, enhancing its capabilities and contributing to the overall success of FLAMA.

1996

Supply and activity diversification

In this pivotal year, FORMAPLÁS undergoes a transformative shift, venturing into the dynamic realm of thermoplastics production. This strategic expansion marks a decisive step toward diversifying its product portfolio and embracing cutting-edge technologies, reinforcing FORMAPLÁS position as a forward-thinking industry leader.

1998

Portuguese Normative NP EN ISO 9001

Achieving a significant milestone, FORMAPLÁS attains certification under the esteemed Portuguese Normative NP EN ISO 9001 for its robust quality management system. This recognition underscores FORMAPLÁS unwavering commitment to excellence and adherence to internationally recognized standards, solidifying its position as a trusted industry player.

1999

PME Leader and PME Excellence

FORMAPLÁS achieves its inaugural recognition as PME Líder, an accolade it has consistently received since then. The company's commitment to excellence is further acknowledged with the conferral of the prestigious PME Excellence title. This dual recognition underscores FORMAPLÁS continuous pursuit of business distinction and its unwavering dedication to achieving the highest standards of performance and leadership in the industry.

2005

Production of parts for the Automotive Industry

Embarking on a new phase, FORMAPLÁS initiates the manufacturing of components for the automotive sector while actively participating in international trade fairs. This strategic move not only expands the company's product portfolio but also amplifies its global visibility, positioning FORMAPLÁS as an active player in the automotive industry on the international stage. The company's foray into the automotive sector marks a significant milestone, reflecting its commitment to diversification, innovation, and global engagement.

2013

40 years of activity

FORMAPLÁS commemorates four decades of excellence, reflecting on its rich history of growth, innovation, and commitment in injection molding, tooling, and assembly services. This milestone highlights the company's resilience, forward-looking approach, and dedication to quality solutions. Cheers to 40 years of success and innovation.

2018

Investment in the Thermoplastics Area

FORMAPLÁS makes a strategic investment in the thermoplastics sector, acquiring state-of-the-art robotic injection machines. This significant move enhances the company's production capabilities, and energy efficiency, and solidifies its position in the automotive sector. The adoption of cutting-edge technology underscores FORMAPLÁS commitment to staying at the forefront of innovation and delivering high-quality solutions to its clients.

2023

50 years of activity

FORMAPLÁS commemorates five decades of excellence, reflecting on its rich history of growth, innovation, and commitment in injection molding, tooling, and assembly services. This milestone highlights the company's resilience, forward-looking approach, and dedication to quality solutions. 50 years of success and innovation.

2024

Our Mission

To create value in the production of components, innovating in product and continuously improving services, responding to the interests of Shareholders, Customers, Employees, Suppliers, Society and Environment.

Being a reference as a manufacturer of components, reinforcing its position in the market and the value chain and investing in product and service innovation. Betting on market research and development to adapt service and product, obtaining benefits.

At Formaplás, innovation drives continuous improvement, ensuring effective, efficient solutions. Our flexible approach adapts to dynamic challenges, all while prioritizing environmental protection.

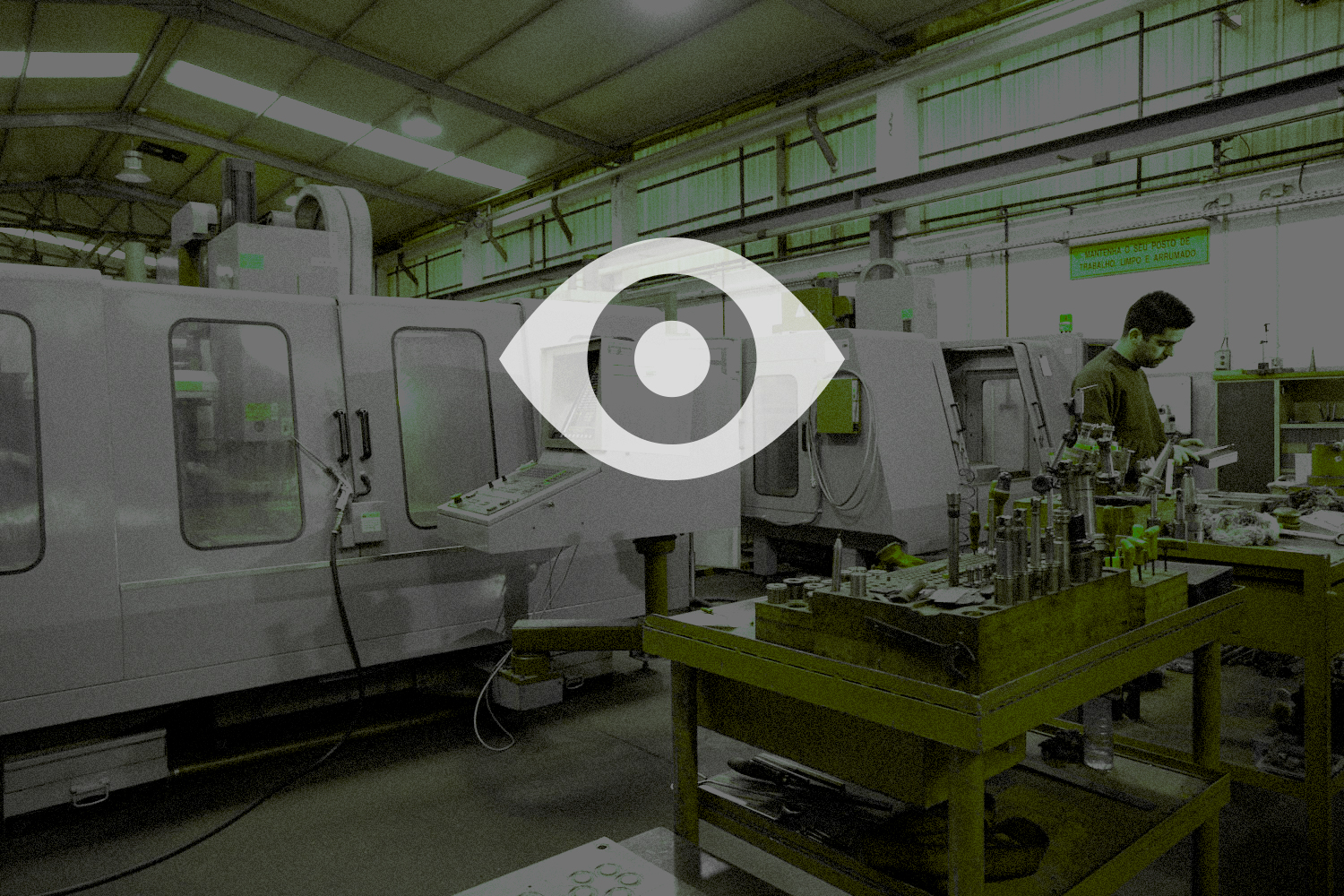

What we do?

Product Development

At Formaplás, we turn your needs or designs into tangible products. Our skilled, multidisciplinary team promptly responds to customer requests, utilizing cutting-edge software tools like Solidworks and Depocam to bring concepts to life, adding value to the evolving product.

Prototyping

Prototyping is crucial in developing new products, providing insights into their physical context and uncovering improvement opportunities. Formaplás utilizes 3D CAD data or printing for production and ensures small series production from prototype molds.

Plastics Injection

Formaplás, with extensive experience, excels in thermoplastics (plastic parts) and thermoset (bakelite) production. Serving automotive accessories to consumer goods components, our focus is delivering top-quality and precise products.

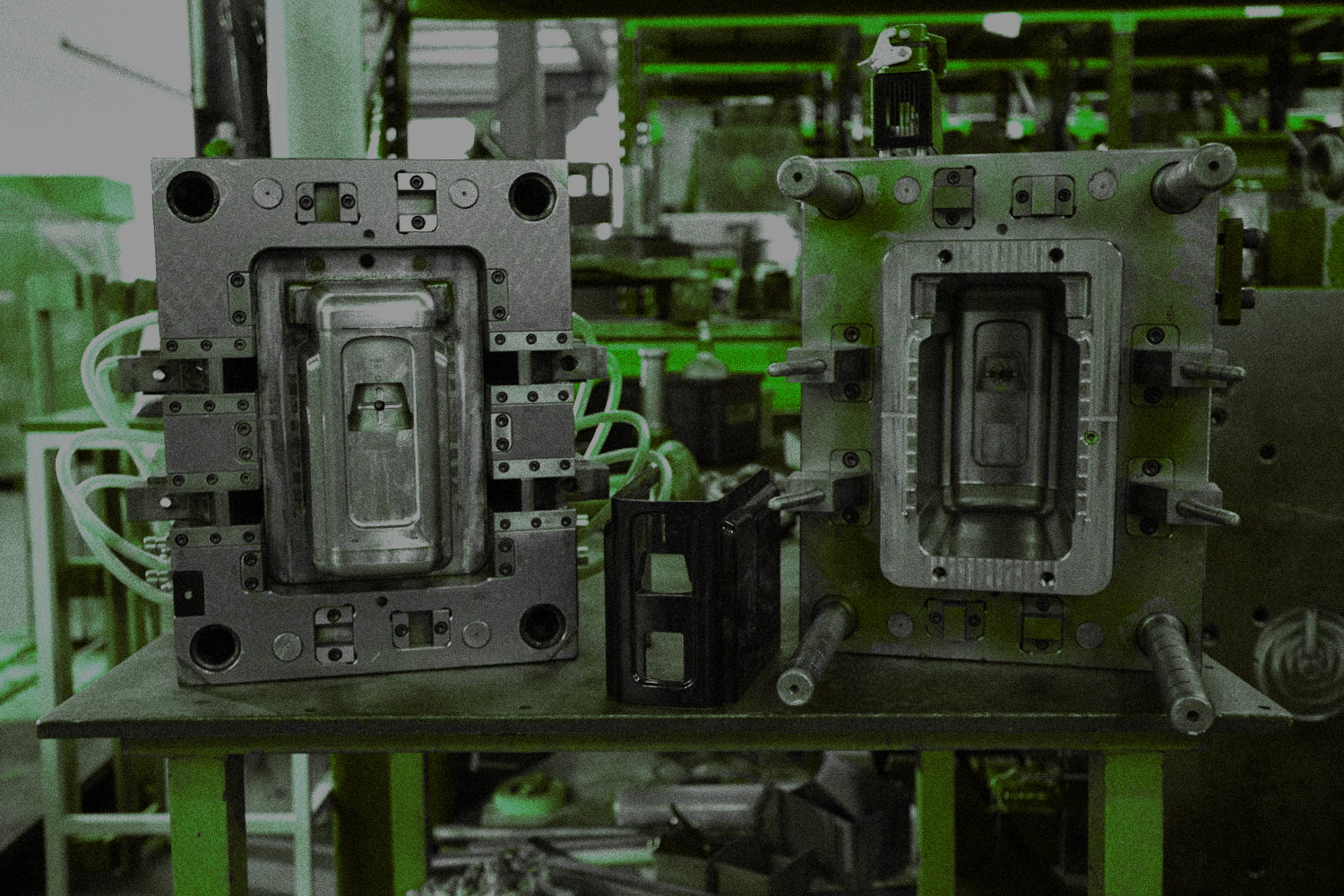

Moulds

Formaplás crafts molds for aluminum casting, complementary tools for injection molding, and cutting/stamping tools for various metal components. In the mold service, we handle entire projects, including new molds, maintenance, and tools application.

Industrial Capacity

STAMPING

We craft diverse metal components for various applications, excelling in transforming raw materials like stainless steel.

WELDING

In the metallics area, our experienced team perform welding operations with all the security.

POLISHING

We have equipment for grinding and polishing the metal parts in order to obtain a glossy or matt finish.

SURFACE TREATMENT

Before being painted metal parts undergo a pickling process which can be carried out mechanically or chemical.

PAINTING & PAD PAINTING

We excel in diverse painting techniques, ensuring high-quality results through advanced equipment and precise markings.

ASSEMBLING

The rigor in execution and quality control performed at each stage ensures a high-quality final product according to customer expectations.

We’re shaping the future since 1973.

Portfolio

Explore our diverse portfolio, where innovation meets excellence.

With a commitment to innovation and sustainability, FORMAPLÁS stands at the forefront of delivering cutting-edge solutions across diverse industries. Our extensive expertise ensures the highest quality, offering tailored solutions to uniquely meet your needs. Explore the depth of our capabilities and experience the value we bring to every project.

Formaplás has the capacity to develop and produce moulds in the most varied technologies. Erosion Penetration (CNC) – Erosion (CNC) – Wire Erosion (CNC) Radial Puncher – Press (Mould Adjustment) – Conventional Milling Machine – CNC Machining Center – Rectifier – Lathe – EFI Drill Mechanical Saw

PLASTICS INJECTION

60 Ton to 400 Ton

ISO 9001 Certified

Formaplás – Transformadora de Plásticos, LDA

Rua Alto de Mirões, nº209 Zona Industrial de Cesar – Apartado 2014 3700-727 Cesar, Portugal

+351 256 850 280

info@formaplas.com

NIF: PT 500 353 824

Group: Flama, S.A.

© 2024 FORMAPLÁS| All rights reserved.

0

0 1

1 2

2 3

3 4

4 5

5